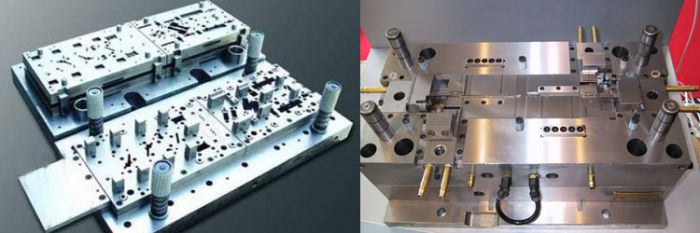

Quality control system for high precision metal stamping parts

Measuring tools:

|

|

|

|

| 2.5 D | CMM | R gauge | Height gauge |

|

|

|

|

| Thickness gauge | Ring gauge | Angle gauge | Caliper |

|

|

|

|

| Torsion meter | Micrometer | Push pull meter | Outside diameter gauge |

|

|

||

| Tooth gauge | Hardness tester |

Inspection items:

| Appearance ( Scratch, Rusting & Oxidation) |

Plating(Thickness & Color) | Material Short Feeding | Poor Forming | Deformation |

| Dimensions | Bending angle | Chamfer | Punch | Thread |

| Burrs | Defective Upsiding Down | Defective Staking | Displacement | Mechanical Property |

Problems to be prevented in transportation & storing:

▲oxidization resulting from fingerprints

▲deformation from accidental fall-off

▲rusting & oxidization problem on sectional area after long-time storing.